System reference

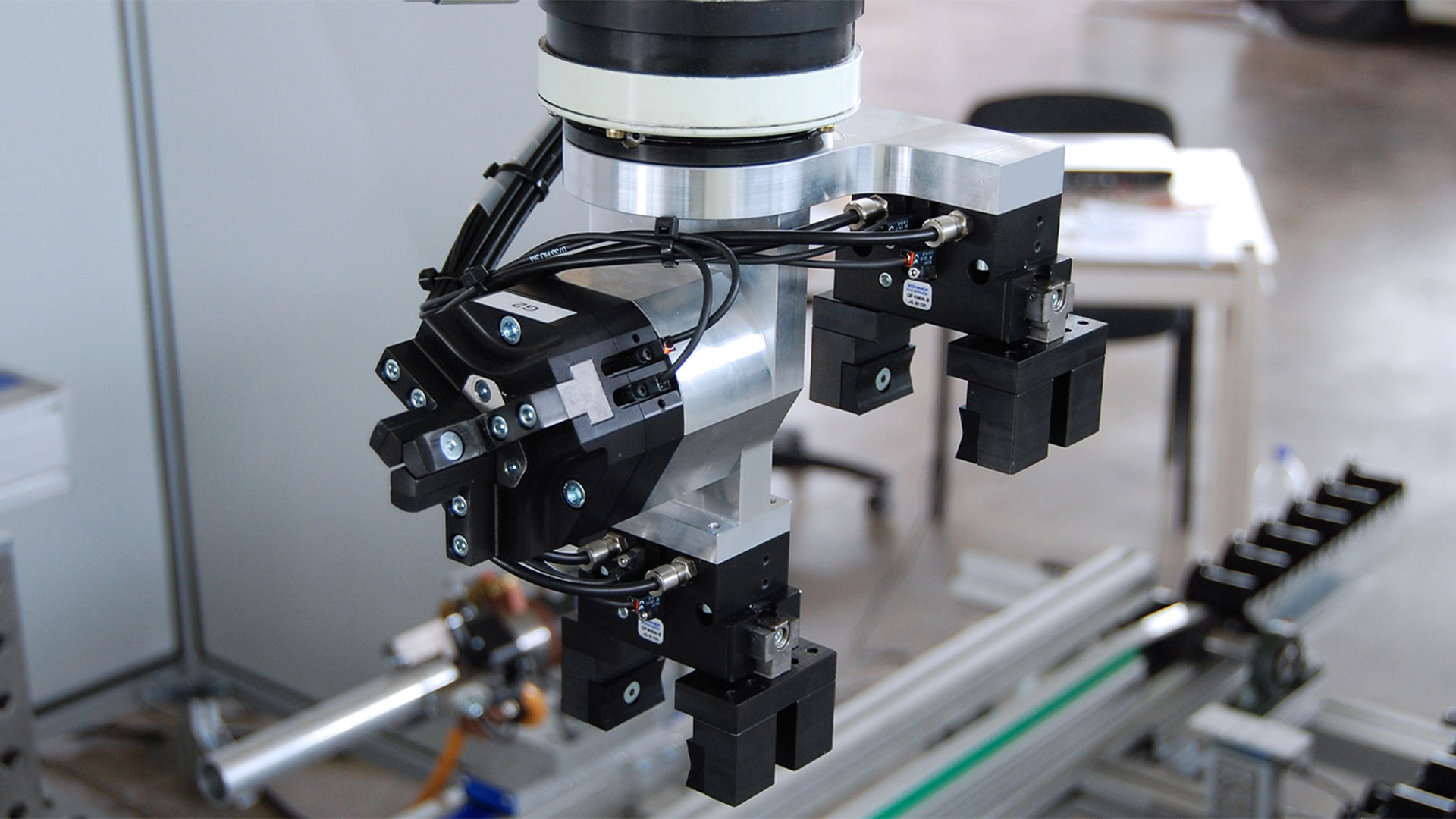

Gripper for shafts

System solutions | Mechanical and plant engineering | Metal | Welding and cutting

3-Jaw Concentric Grippers

Series GD300

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2-Jaw Parallel Grippers

Series GP400

- High gripping force as a result of optimal direction change of driving force into gripping force

1. 3-jaw concentric grippers

- Extremely robust T-Slot guide for maximum forces and moments capacity

- Available with optional dust cover for use at extreme conditions

2. 2-jaw parallel grippers

- High gripping force as a result of optimal direction change of driving force into gripping force

Challenge

In the production of garage doors by Europe's largest garage door manufacturer, steel shafts needed to be supplied to a MAG welding system. Harsh ambient conditions and rapid cycle times posed a particular challenge.

Solution

The solution was a triple gripper for various steel shaft types. The gripper can grab using both the front and the longitudinal sides. The use of rugged standard grippers ensures a long service life with maximum process reliability.

Highlights and technical data

IP40

IP40 Pneumatic

Pneumatic External gripping

External gripping

Technical Data

| Drive type | PNEU |

| Max. gripping force | 750 [N] |

| Gripping concept | KRAFT |

| Gripping safety device | DRUCKSICHER |

| Max. stroke | 12 [mm] |

| IP class | IP40 |

| System weight | 5 [kg] |

| Max. workpiece weight | 0.3 [kg] |

| Max. workpiece temperature | 80 [°C] |

Built-in standard components